1 Leveling the transport system to the solder wave

2 Evaluation of smooth solder pump performance

3 Adequacy of flux distribution and thickness.

This unique method of topside observation of the actual wave-to-board" contact

provides added opportunity for precise analysis of your own particular process. LEV CHECK

is helpful in identifying proper angle of contact, flux and / or oil intermix,

displacement, flushing action, direction of solder flow, and meniscus velocity at the

break away "trailing edge" of the solder contact. It also allow visual

observation of wave impingement on board surface and turbulence.

How to

Use

LEV CHECK

Solder Wave Gauge is easy to use. The basic principle is to simulate all condition as

close as possible to your own production process. This means fluxing, preheating, conveyor

speed etc. to be kept the same as if soldering actual printed wiring boards. Simulating

these conditions will demonstrate visibly how your process works. Place glass with grid

pattern side facing up.

Flux Application Visual observation of the pattern of the flux wave or foam head through

the transparent LEV CHECK gauge monitors adequate, uniform quantity of flux application.

Subsequent action to air knife or brush control can be monitored and precisely adjusted to

prevent wasted and fire hazard of flux spillage on preheaters.

Preheater

Effectiveness can be observed for controlled evaporation of flux solvent prior to entry

into hot solder wave

Evaluation Of

the solder wave may be done into two different ways.

1 Dynamic Test is a fast "qualitative" method

performed by simply running the LEV CHECK gauge across the entire soldering operation at

the same continuous rate as a standard production PWB.

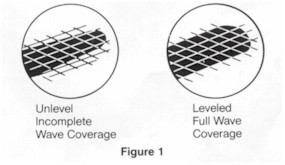

Observe uniformity of solder sweep across entire width of contact surface. The total area

of glass contacted by the solder wave illustrates the immersion depth of the board in the

solder. Trailing edge at break away of solder from gauge should show a minimum of

1/32" of flux line - a good indicator for reducing tendency for icicling. The

velocity of meniscus of solder draining should be greater than the velocity of board over

the soldering machine. Simple observation will allow swift adjustment of conveyor speed or

wave height. The "float effect" due to impingement action of solder wave and

thermal gradient produced on the board can be observed and controlled by fixture

adjustment, conveyor speed and temperature of solder.

2 Stationary

Test is stopping the conveyor with the LEV CHECK gauge centered across the solder

wave within the marked gauge lines. This test is "quantitative" as now the

precise contour can be seen as well as the total area of contact with the solder. If the

width of the wave is not uniform at each end as line up by the gauge lines as seen in

Figure 1, then leveling adjustment may be made while the LEV CHECK gauge is still in

place.

To determine

contact time, place gauge on conveyor using normal speed. Measure width of wave as glass

is centered on solder. Conveyor may be stopped briefly to obtain width. Contact time and

the resulting time/temperature ratio can be calculated by multiplying thickness of wave

observed on gauge by 60 sec/min. and dividing this product by conveyor speed in inches per

minute.

Effective

action of flux and solder depend upon minimal time/ temperature of solder contact. On the

other hand, a long dwell time at too high temperature may damage both thermal sensitive

components as well as delicate board substrates.

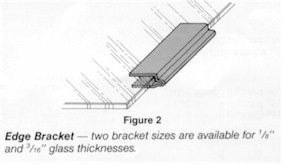

The purpose of

the edge brackets is to set the bottom of the glass plate at the same level as the

bottom of the PWB (as shown in figure 2.) The edge brackets are made from 0.020"

titanium and are sold for specific glass thickness 1/8" or 3/16" and come in

sets of four to a package.

This tempered

glass panel has been designed to withstand normal heat of soldering for short duration.

The glass will not tolerate thermal shock as well as a laminated epoxy glass

substrate and certain precautions should be taken to prevent accidental breakage. Do not

force the glass into a fixture or mount it too tightly. Expansion from heating may

increase risk of breakage. Soldering temperature of 500-525 degrees F will not

adversely affect the LEV CHECK. Normal transport speeds across preheaters are acceptable,

and stationary dwell time on wave for observation is allowable for up to 30 seconds.

Temperature above 525 degrees F require extra precaution to reduce the sudden build up of

uneven thermal strain on the glass. At these higher temperature the use of a slower speed

across the preheaters is suggested. Do not hold the glass panel stationary

on the solder wave longer than thirty seconds.

When

to Use

How often the

LEV CHECK gauge is used depends on the degree of the process control you need to satisfy

you company's quality requirements. Time required for the dynamic test as a routine

quality check of the wave process is not much longer than the cycle time of soldering a

standard production board. This makes frequent monitoring easy and inexpensive without

costly delays of production interruption.

As a general

rule, the gauge should be used a the start of each shift. If many different sizes of board

are used or the wave parameters are changed an additional test is recommended.

Caution

Do not expose

glass to soldering heat without flux and preheat cycle.

Do not position gauge so glass extends beyond width of solder wave. Choose gauge or wave

width so that solder spreads completely across the width of LEV CHECK gauge.

Position LEV CHECK for use with marking side up.

The LEV CHECK Solder Wave Gauge is tempered borosilicate glass specially designed to

withstand the extreme thermal shock of a typical 525 degrees F solder wave. Do not try

this with ordinary glass.

Although it has good mechanical strength and excellent impact properties, (5 times as

strong as standard annealed glass) it is sensitive to mechanical stress on the corners and

edges. Do not force it or mount tightly in a rigid holding fixture. Expansion from heating

may cause unusual mechanical stress and together with the thermal shock increase the risk

of breakage. Because of the nature of this tempered glass, if breakage should occur. the

glass may shatter completely into "gravel type" particles not needle sharp

silvers like ordinary window glass. Any glass particles will float on the solder surface

and are readily removed.

Use all normal safety precautions while observing LEV CHECK including safety glasses.

Cleaning

and Storage

Allow LEV

CHECK gauge to cool before handling. Because it is thicker than a production PWB, it will

take more time. Do Not Chill the hot glass suddenly. Allow it to air cool. Clean off

excess flux remaining with suitable solvent. Dry and replace glass gauge in its

protective bag and envelope. Store LEV CHECK carefully. It is more likely to be

broken through careless handling than from heat. Bookcase or file drawer storage is

advised . Use the shipping box for convenient storage.

Stock Standards

Model LC810

8"x10"x1/8" 1/2" parallel gauge lines

Model LC1510 15"x10x1/8"

1" square grid lines

Edges Brackets

Model LC 125 adapts 1/8" thick

glass to 1/16" fixture.

Model LC 187 adapts 3/16" thick glass to 1/16" fixture.

|